Update: October 18, 2024

A new page for the Sewage Treatment Plant has been created, featuring updates since the September report. Please visit: https://townofantigonish.ca/sewer.html.

Post from September:

In response to growing concerns being raised by our residents regarding the odour coming from the Sewage Treatment Plant (STP), we would like to provide an update on its operations and answer some of your questions regarding the plant’s capacity, why there is a smell, what is being done to address the smell, etc.

We acknowledge the odour that comes from the plant has a negative impact on residents, businesses, and visitors. The facility and the issues are complex, but we assure you the plant is running how it should treat wastewater. There have been no mechanical breakdowns and the odour you smell is not harmful to your health.

The smell is stemming from a variety of factors including warmer temperatures, an accumulation of sludge, and the need for improvements to the process of introducing air (or oxygen) into the wastewater. We have identified action items to address these issues however they are medium- and longer-term solutions. In the short term, staff are at the plant every day adding deodourizer to the lagoon to help with the odour. Staff have also responded to feedback by monitoring odour outside of the STP fence and beyond regular business hours.

If you are wondering if the odour is dangerous at these levels, please understand it is not. Town staff are at the plant every single day monitoring its performance, performing maintenance and other tasks. We value our employees’ safety and are legally required to keep them safe. There are gas detectors at the plant to monitor gas levels to ensure they are safe. The readings from these instruments have not registered levels to raise health concerns.

We recognize there has been limited information shared about our Sewer Treatment Plant and we apologize for that. We realize this communications gap has made room for many rumours to be created and misinformation is circulating about the plant’s capacity, what is causing the recurring smell, and that the smell is harmful to human health. In an effort to address all these issues we are using a Frequently Asked Questions format.

What is causing the smell?

There are several factors creating the offensive odour:

With climate change and hotter summers we have been having, the temperature of the lagoon is six to seven degrees warmer than what the STP has been configured for. Hotter water temperatures decrease oxygen transfer / retention in the plant and results in increased odours.

The accumulation of sludge, made up of settled biomass and inorganic material (material that shouldn’t be flushed) is also adding to the plant’s current issues. This extra sludge makes it difficult to treat incoming wastewater as it encases the aerators (used to increase oxygen levels) and increases the amount of treatment needed in the lagoon.

The plant has noticed a periodical increase in the strength of incoming wastewater. This is likely due in part to growth in the area, but mainly because the sewage collection system has been improved to reduce stormwater entering the system. As a result, the wastewater is stronger in concentration, but there's less of it in the lagoons, especially when warmer weather lasts longer.

Will it ever not smell?

Let’s be clear, healthy lagoons will always have a smell; but not an offensive smell like we have had recently. Due to the nature of the plant and the business of treating sewage, there will always be a musky smell, but that smell should never leave the plant under normal operating circumstances.

We recognize the offensive smell we have experienced lately is not normal. We have short-term measures, the addition of deodourizing products, medium-term actions such as plant desludging, and long-term actions including upgrades to the STP, we are taking to address this odour.

What can help the smell or the treatment process?

In the Spring of 2024, there were a few weeks with a very strong odour coming from the plant. We know it had a severe impact on residents. We hired a consultant to conduct an analysis of the STP. A preliminary overview of their findings has recently been received by the Town. The following causes were identified as contributing to the odour:

- Climate change and warmer summers are causing summer lagoon temperatures to be approximately six to seven degrees warmer than was typical 20 years ago. Hotter water temperature decreases oxygen transfer efficiency, possibly in the range of 15 - 20%. There isn’t enough oxygen getting transferred into the wastewater in the lagoon.

- Sludge accumulation and its effects on equipment (buried aerators, etc.) are also projected to have a combined 10 - 20% decrease in oxygen transfer efficiency. The STP has historically had sludge removed on a ten year cycle. With increased population growth over the past decade, the volume of sludge, as we near our ninth year since the last desludging, is approaching capacity.

- The influent strength has periodically increased this summer over the design loading for the plant. The STP was designed for a certain concentration of material coming in and we can periodically exceed that level.

A number of action items have been identified to address the causes identified above:

- Increase recirculation within the lagoon to bring more oxygenated water from the back of the lagoon to the front end.

- Note: This action was started within 24 hours of receiving the preliminary report.

- Desludging of the lagoon will alleviate the oxygen demand that the sludge is creating.

- Note: the lagoon is desludged every 10 years. The lagoon was last desludged nine years ago. It is our intent to have it desludged by the end of the year. Town Council approved a motion at the September 16th regular council meeting to have staff proceed with this work. When the lagoon is desludged, over 60 tractor trailer loads of material will be removed, and oxygen demand will be decreased.

- Install new equipment for increased efficiency of the front-end aerators.

- Note: Consultations have begun on installing a new blower and creating separate pressure zones for aeration equipment to improve the efficiency of the plant.

- Installation of a surface aerator on the front of the lagoon would provide some additional spot aeration.

- Note: This option is currently being assessed.

- Colder temperatures as we get into fall and winter will bring relief by increasing the oxygen transfer efficiency.

- Installation of a screening system, announced earlier this summer, will aid in reducing load.

- Note: Currently, the STP does not have a screening system. The plant has a grinder that shreds incoming materials into smaller pieces so they can be pumped into the lagoon. This means the plant doesn’t have a method to prevent material that shouldn’t be flushed from entering the lagoon, and we are currently dealing with treating the increased loading and smells from that material.

- In June of 2024, the Province of Nova Scotia announced they would contribute $2.7 million towards a new screening system. The Town will be adding $1.8 million to that amount and the Municipality of the County of Antigonish will be contributing $900,000. That’s over $5.4 million in upgrades coming in 2025.

- This upgrade will put in place equipment to remove, de-water, and dispose of solids and inorganic screenable materials (pads, tampons, condoms, wipes, etc). Upgrading the STP infrastructure will also include new lift station pumps and aeration blowers.

- Consider a full upgrade of the aeration system.

- Note: This would be a major undertaking and will be assessed as part of future planning.

Is the plant overcapacity?

One statement we often see shared on social media is that our plant is overcapacity. When talking about the capacity of the plant there are two different types of capacity to refer to: flow (hydraulic) and treatment.

Flow capacity refers to the amount of wastewater that can flow through the plant. For most of the year, flow is not an issue. It can become an issue in the wet seasons (or extreme weather events), when river water levels are high and there is increased inflow / infiltration affecting the pipes in our collection system. Efforts to reduce extra stormwater entering the system are ongoing, and all users are encouraged to check their properties for ways to help, such as making sure eavestroughs and foundation drains aren't connected to the sewer system.

Regarding the treatment capacity, the STP has been noted by consultants to produce good quality treated wastewater. However, the plant’s capacity can be affected by the accumulating sludge as this reduces oxygenation and effectiveness of pumps and aerators in the lagoon.

With the planned upgrades (including a new screening system) and a desludging this year, we will be able to restore the plant’s treatment efficiency and support the community’s current and future growth.

Can it handle further growth?

A statement we often see online is that the STP can’t handle the expansion we’ve seen in the fringe. With modest upgrades (which are coming) we do have the ability to expand what we have and support our community’s growing population.

Do we need a new plant?

No, we do not need a new plant. For what the plant is supposed to do, treating sewage, the lagoon performs well and has a good treatment efficiency.

Our STP was originally built in 1974 with $3 million of upgrades made in 1996. We have plans to spend over $5 million at the plant starting in the next year and are evaluating for further possible changes to reflect our current environment and issues identified by external consultants.

How does the STP work?

We have an aerated lagoon STP that uses biological processes to consume waste and clean wastewater, before it is released back into the environment. Here’s how it works:

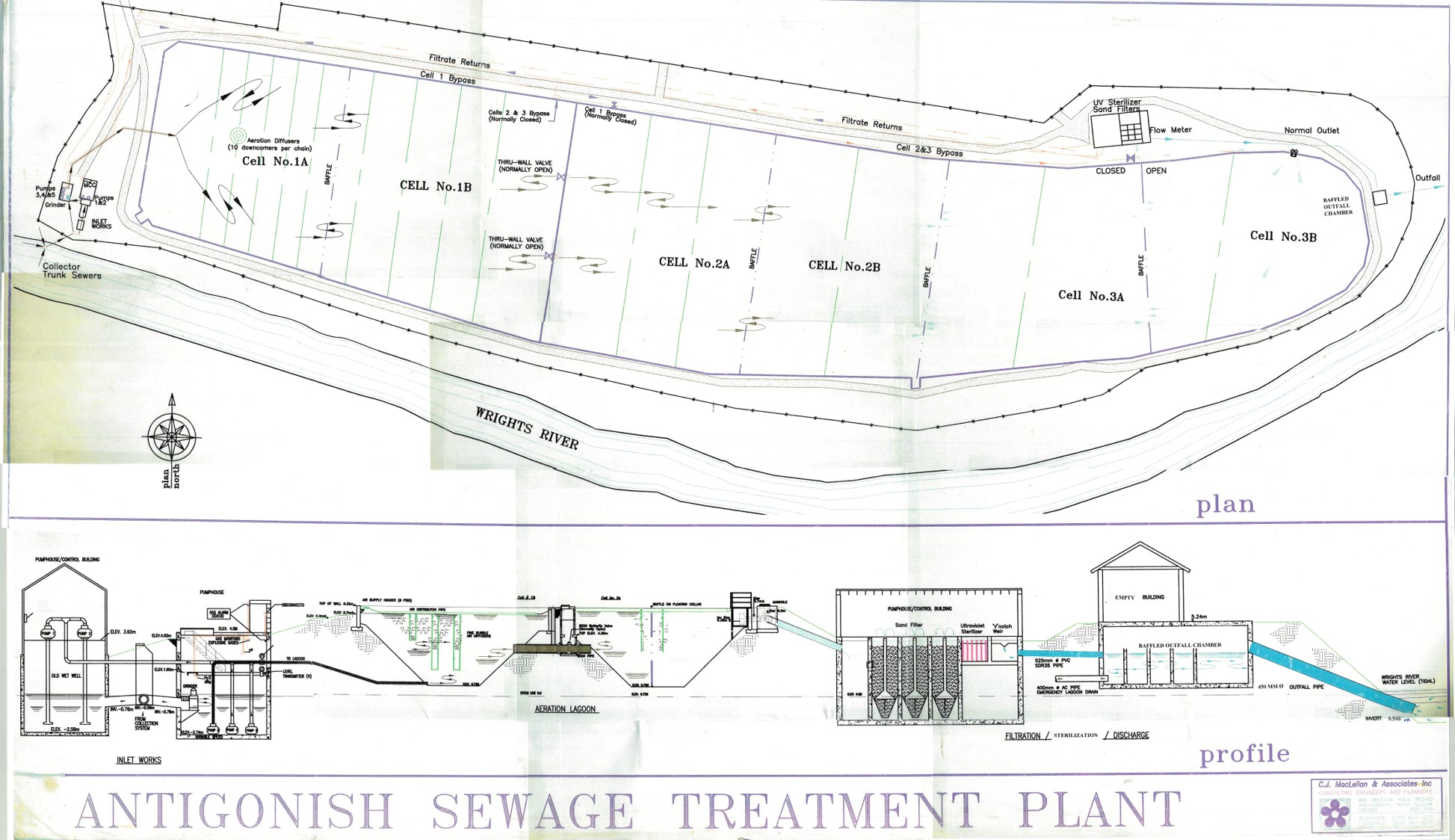

- Headworks / Pre-Treatment: The first step of our STP process occurs when the sewage enters our plant. It flows by gravity through a grinder, which shreds material into pieces so they are small enough to pass through our pumps. The pumps then lift the sewage 25 feet underground up into our lagoon.

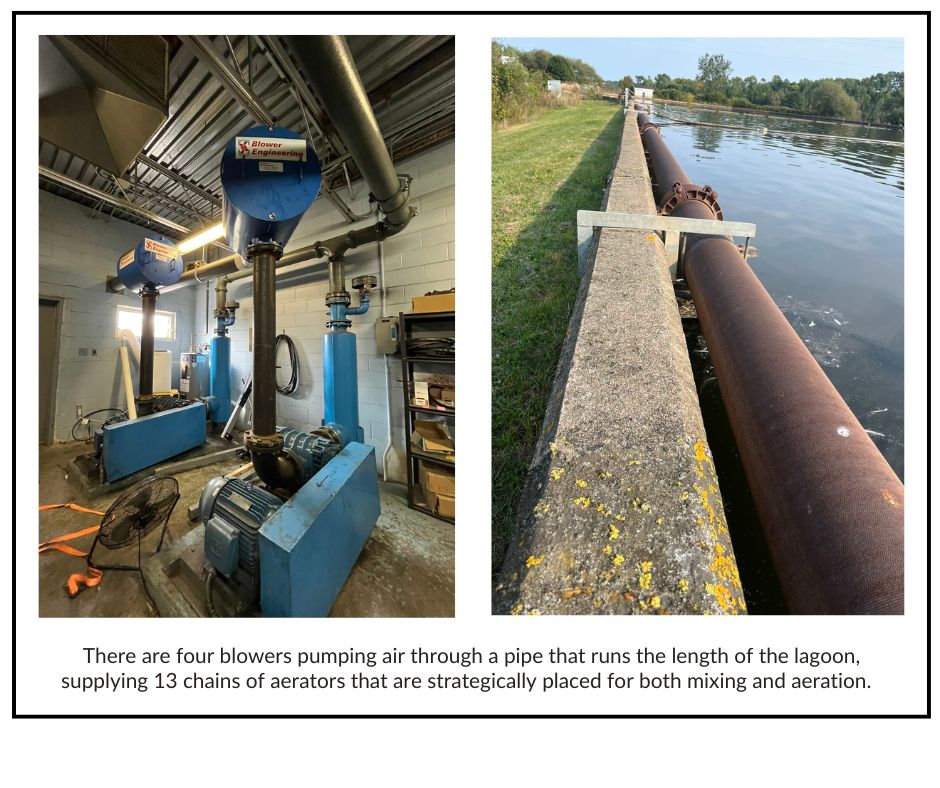

- Aerated Lagoon: The next step involves using aerobic bacteria and other microorganisms (biomass) to break down the sewage in the aerated lagoon. These microorganisms feed on waste, cleaning the water naturally. This process happens in the first five (out of six) cells of the lagoon, with most of the aeration and waste breakdown focused in the first cell. In the lagoon, air is used to help the bacteria grow and do their job. There are four blowers pumping air through a pipe that runs the length of the lagoon, supplying 13 chains of aerators that are strategically placed for both mixing and aeration.

- Clarification: After the biological treatment, the water moves to the final cell in the lagoon. Here, any remaining solid particles, including the biomass (dead bacteria), settle to the bottom, leaving the clarified wastewater on top to flow through three modules of three banks of sand filters.

- Disinfection: To make sure the wastewater is safe to release, it is disinfected with UV light, which reduces (kills) pathogens and bacteria down to acceptable levels.

- Release: Finally, the treated wastewater (effluent) is released back into nature, into the river to rejoin the water cycle. This is a standard practice regulated by the Nova Scotia Department of Environment and Climate Change.

It takes about a month for the wastewater to go through this process. This method is effective and environmentally friendly, using natural processes to treat wastewater.

STP Facts:

- The lagoon at the STP is shaped like a kidney and is 1,500 feet long. That is the equivalent of five U.S. football fields.

- The lagoon is 14 feet deep in its centre.

- It is divided into six cells.

- Of the 13 chains of aerators, 70% of those are located in the first two cells where most of the sludge can be found.

Let’s Talk About How YOU Can Help Our Sewer Treatment Plant!

Did you know that every couple of weeks, we have to vacuum out non-organic materials like menstrual products and garbage that are floating in our lagoon? These items block our aerators and affect the plant’s efficiency.

While we have plans to invest $5 million in a new screener to filter out this material, you can help now by being mindful of what you flush. Only flush toilet paper and human waste — every small action makes a big difference!