Town of Antigonish Sewer Treatment Plant

Last Update: Oct 10, 2025

The Town of Antigonish is committed to keeping the public informed about our Sewage Treatment Plant (STP) and ongoing efforts to improve capacity and address odour concerns.

Current Odour Response & Mitigation

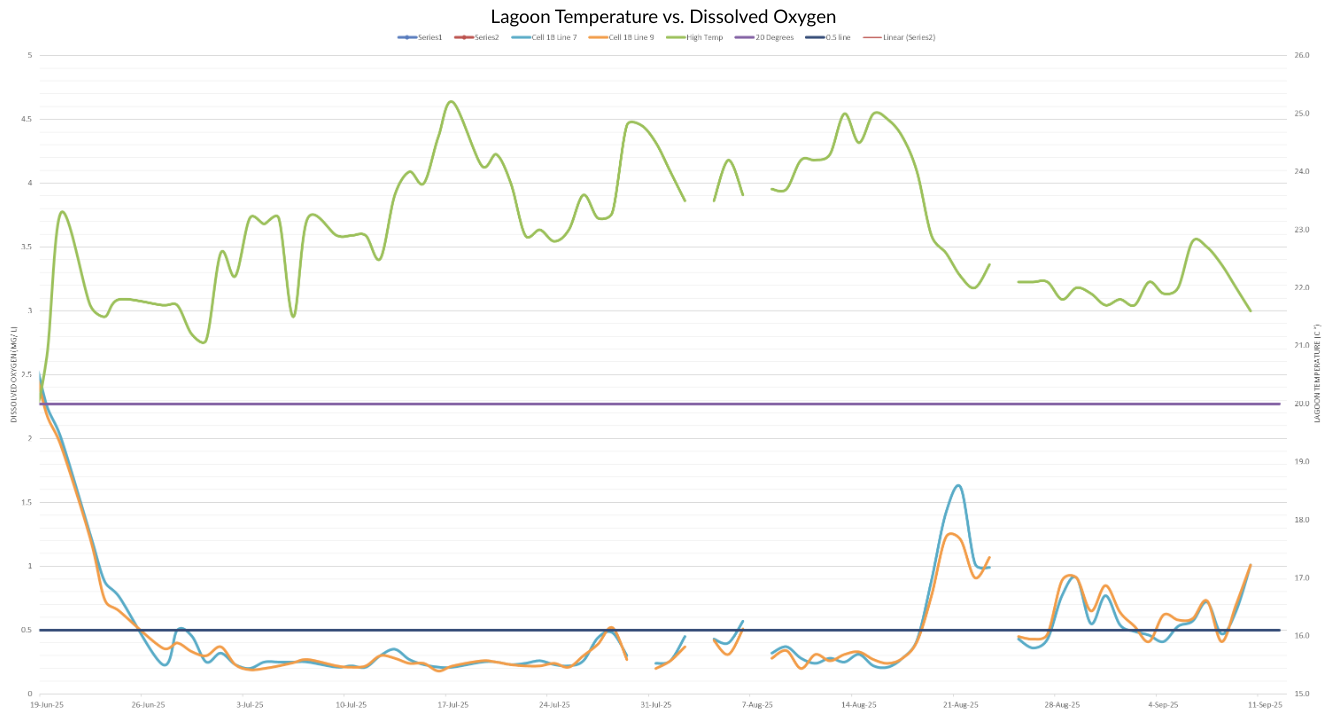

In early July, people started noticing stronger smells coming from the lagoon. This happened around the same time as a stretch of very hot weather. The lagoon’s oxygen levels drop when water temperatures rise above 20°C. This is a threshold the plant wasn’t originally designed to exceed. Less oxygen means more odour. As of August 14th, the odour event was no longer normally detectable outside the Plant fence line, and by September 1st, the odour was no longer detectable inside the fence line.

As observed, the apparent change in oxygen levels corresponds with the start and end dates of the odour issue. While the oxygen is still fluctuating with changing temperatures, our team continues to work hard at keeping the odour at bay with their intensive recirculation efforts.

To fight the odour, here's what our team has done:

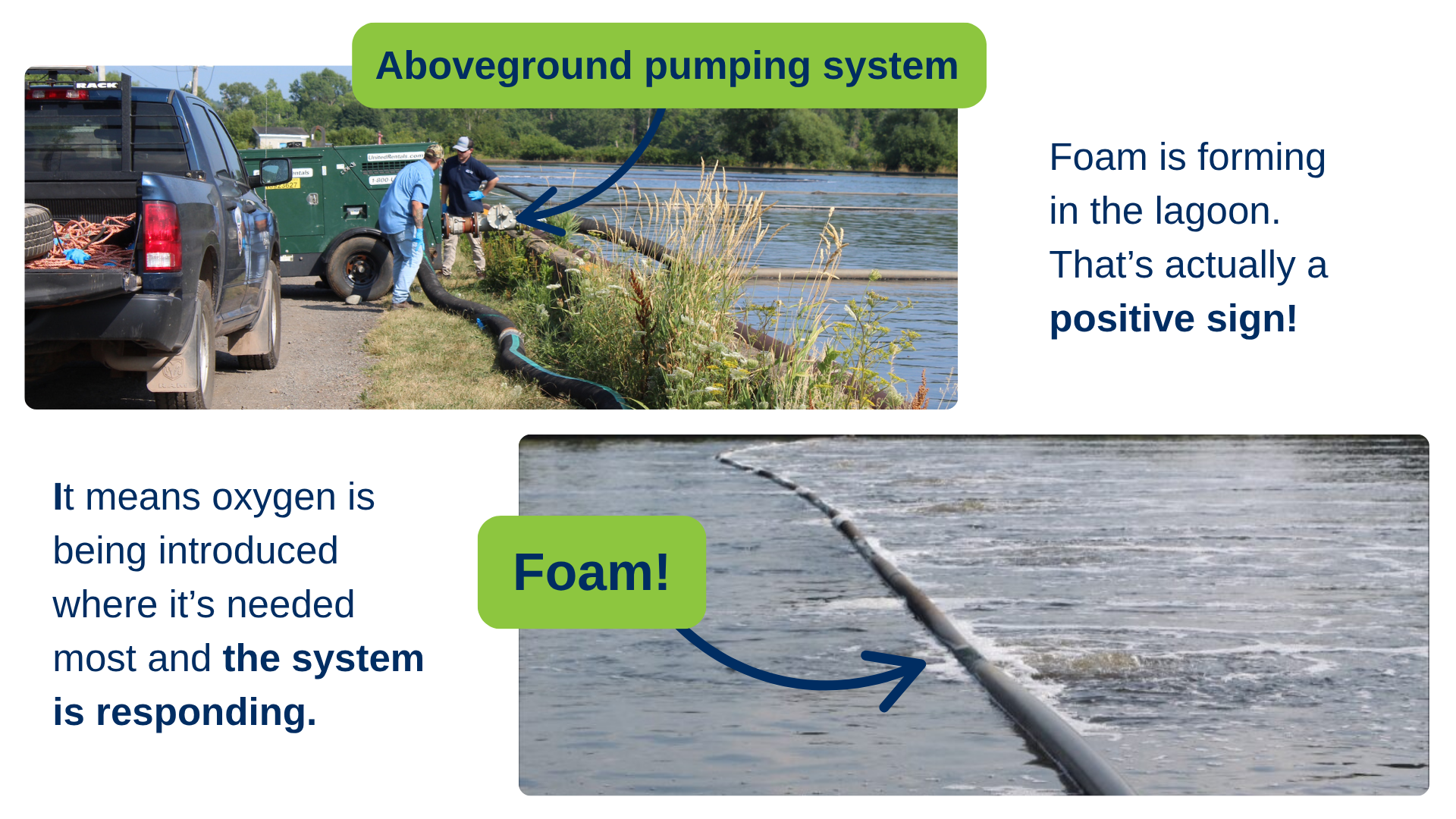

- Moving Oxygen-Rich Water to the Front: With advice from engineering consultants, we began recirculating water from the back of the lagoon to the front. This brings oxygen-rich water into the area where oxygen levels are low. We’re using existing infrastructure to do this and are now installing an aboveground pump to increase the flow even more. You may notice foam forming on the water—that’s actually a good thing. It shows that oxygen is entering the system where it’s needed.

- Adding Cold Water: To help reduce temperatures and improve oxygen levels in the lagoon, we safely added cold water through the recirculation system for short periods earlier this summer. This approach showed positive results in reducing odour and will remain an important tool for future use once water levels are restored.

- Using Deodorizers: Two types of deodorizers have been fully automated at the plant this September, further strengthening efforts to control and reduce odour.

- Removing Sludge: Back in January 2025, we removed about 2 metres of sludge from Cell 1 of the lagoon—equivalent to 300 bone dry tonnes or 36 trailer loads. This helps with oxygen flow and reduces the amount of waste that bacteria have to break down, which helps cut back odour.

.png&routed=1&view=file) Cleaning Out Debris: Cleaning Out Debris: Our team has been working hard to remove rags and debris from the aeration system, which currently operates without a screening system. With more floatables appearing in September, operators have stepped up removal efforts and added spot treatments to help reduce odour.

Cleaning Out Debris: Cleaning Out Debris: Our team has been working hard to remove rags and debris from the aeration system, which currently operates without a screening system. With more floatables appearing in September, operators have stepped up removal efforts and added spot treatments to help reduce odour..png&routed=1&view=file)

- Ongoing Odour Monitoring: Our team checks odour conditions daily and adjusts aeration and surface skimming as needed.

Aeration Action & Awarded Tender

We’ve taken significant steps to improve air circulation and reduce odours at the wastewater treatment plant. Additionally, blower systems are being refurbished to further support these enhancements.

In a tender recently awarded to Nexom on October 8th, 2025, our aeration equipment upgrades project involves upgrading aeration equipment at our multi-cell wastewater lagoon. The new system, which includes aeration units, tubing, air distribution manifolds, and more, will enhance treatment performance and energy efficiency while integrating seamlessly with the existing facility.

Awarded Screening Tender

A recent tender was awarded to Veolia Water Technologies for a pre-purchase of screening equipment for the sewer treatment plant. This equipment will help prevent solid materials, such as wipes, pads, and other non-biodegradable items, from entering the lagoon. This will help protect the plant's equipment, reduce smells, and improve overall treatment.

Plant Upgrades Underway

We’ve partnered with CBCL Limited to make important improvements to the treatment plant. These upgrades will help us deal with odour issues and prepare the system for future growth.

The main part of this upgrade is a new screening system that will stop solid materials—like wipes, pads, and other non-biodegradable items—from entering the lagoon. This will help protect equipment, reduce smells, and improve treatment overall.

Other parts of the project include:

- A new building to house screening equipment, air blowers, a lab, and office space

- Extra aeration equipment at the front of the lagoon

- A backup power system

- Flow monitoring to track how much wastewater enters the plant

Timeline:

- Design began: Spring 2025

- Equipment tendering: August 2025

- Construction begins: Fall 2025

- Completion target: Summer 2026

Funding:

- $2.71 million from the Municipal Capital Growth Program

- $1.8 million from the Town of Antigonish

- $903,000 from the Municipality of the County of Antigonish

- Total project budget: $5.4 million

CBCL Limited is responsible for design, tendering, and construction oversight. The contract for their work is valued at $464,850 + HST.

What We’ve Learned from the 2024 Report

In 2024, the Town hired consultants to assess the source of odour issues. The report found:

- Lagoon temperatures are now 6–7°C warmer than 20 years ago

- Warmer water has reduced oxygen transfer efficiency by 15–20%

- Excess sludge and buried aerators further reduce oxygen by 10–20%

- Removing stormwater from the sewer system increased sewage concentration

The report is is publicly available pdf here(2.90 MB) . This report has been reviewed in accordance with Part XX (Freedom of Information and Protection of Privacy – FOIPOP) of the Municipal Government Act (MGA). The few redactions in the report, cost estimates and plant designs, have been made in accordance with sections 477 (1) and 475 (1) of Part XX of the MGA.

Capacity and Growth Planning

Our STP is permitted to treat 1.8 million gallons per day (MGD). We’re currently averaging 1.65 MGD, putting us close to capacity during rainy weather and high-usage periods.

What affects our capacity?

- Inflow and Infiltration (I/I): Groundwater from leaky pipes or stormwater from roof drains and sump pumps can enter the system and use up treatment space

- Non-flushables: Wipes and other items clog pipes and block aerators

On dry days, flow is about 1.46 MGD. On rainy days, it spikes. Reducing I/I lets us preserve capacity without major expansions.

Short, Medium & Long-Term Actions

The Town of Antigonish remains committed to ensuring the long-term functionality and sustainability of this critical infrastructure as it provides essential services to the community. A number of action items have been identified to address the causes identified above and have been sorted according to the timeframe in which they can be done.

Short Term (Daily/Ongoing Actions):

- Monitor and record odour conditions (Done daily)

- Apply deodorizer products (Done daily)

- Adjust plant aeration equipment (Done regularly)

- Skim surface floatables (Done regularly)

- Flow recirculation to the front of the plant (This action was started in September 2024 and is ongoing)

Medium Term (1 to 3 Months):

- Investigate airflow improvements: CBCL and Town staff are reviewing ways to deliver more air to the lagoon's front section. This includes examining aeration layouts and blower performance.

- Assess blower systems: Electrical capacity, mechanical condition, and pipework are being reviewed to determine if existing blowers can be optimized or if additional equipment is required.

Long Term (4 to 18 Months):

- Construct new screening/blower building: This includes installing screening equipment, backup power systems, flow monitors, and upgraded lab and control spaces.

- Implement blower and aeration upgrades: A new layout will improve airflow efficiency and reduce blockages. These upgrades will provide redundancy and greater control over lagoon aeration zones.

- Ongoing system evaluation and reconfiguration: As new equipment is installed, performance data will guide further changes to aerator positions, pipe sizing, and long-term lagoon operation planning.

Frequently Asked Questions

Will the plant ever be odour-free?

No. A lagoon will always have a slight musky smell, but the strong odours we experienced in 2024 are not normal. With better maintenance and upgrades, these issues can be reduced.

Can the plant support future growth?

Yes. With these planned upgrades, we have the capacity to serve the growing population, including fringe development.

Do we need a new plant?

Through current and planned capital investments, combined with ongoing maintenance, the STP will meet the needs of Antigonish both now and in the future, at a lower cost to taxpayers than constructing a new treatment facility.

Why do we need to desludge more often now?

The lagoon was built to hold about 10 years of sludge. But with population growth and climate change, we now desludge based on how much sludge is present—not just time.